Acciona/DDB

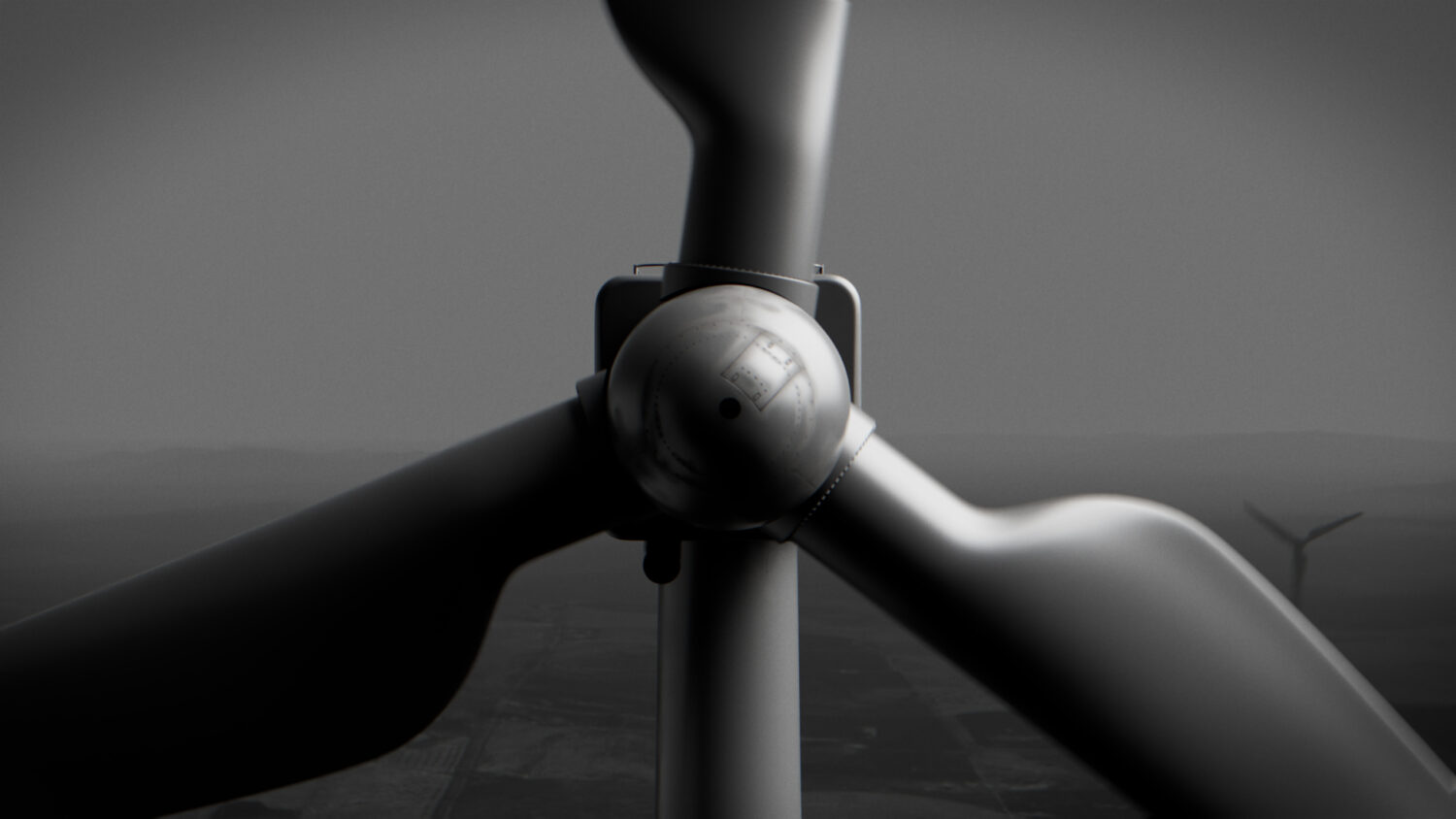

Turbine Made

The studio created this project via DDB Melbourne for ACCIONA, a global leader in renewable energy and sustainable infrastructure, to promote the Turbine Made initiative. This initiative seeks solutions to give retired wind turbine blades a second life and aims to engage industry, sustainability advocates and other potential partners to identify potential new applications for the material.

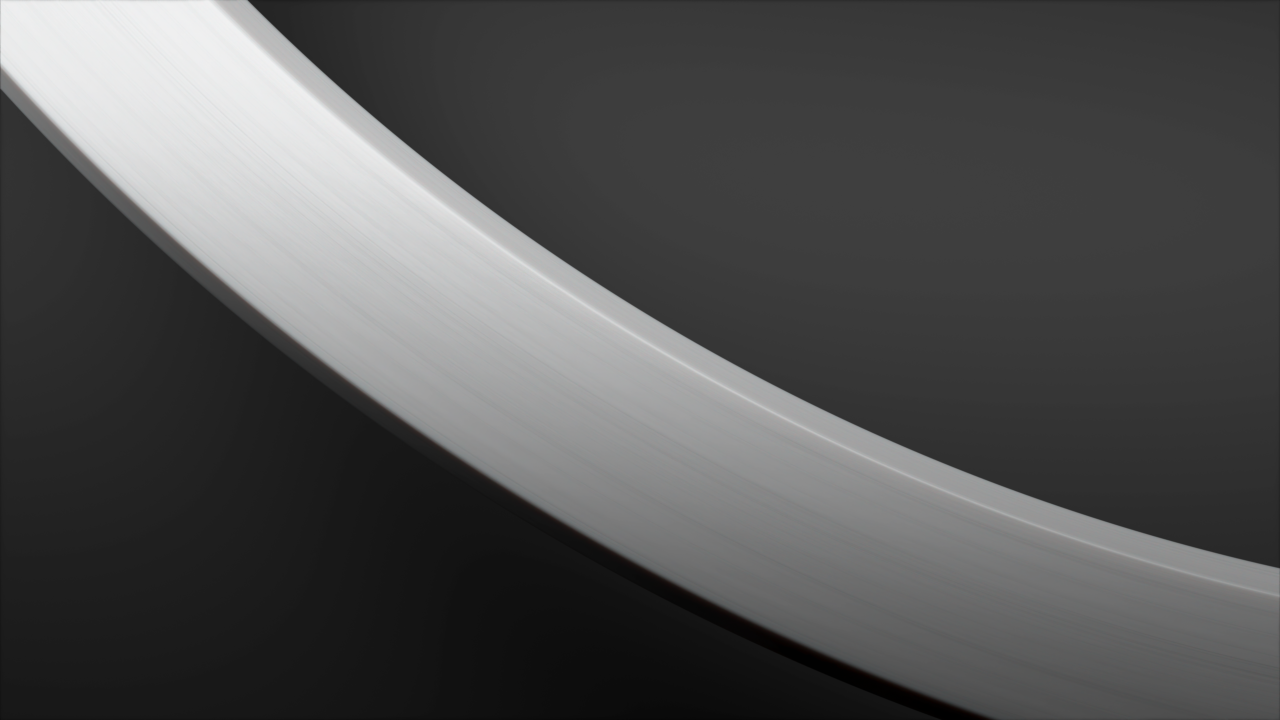

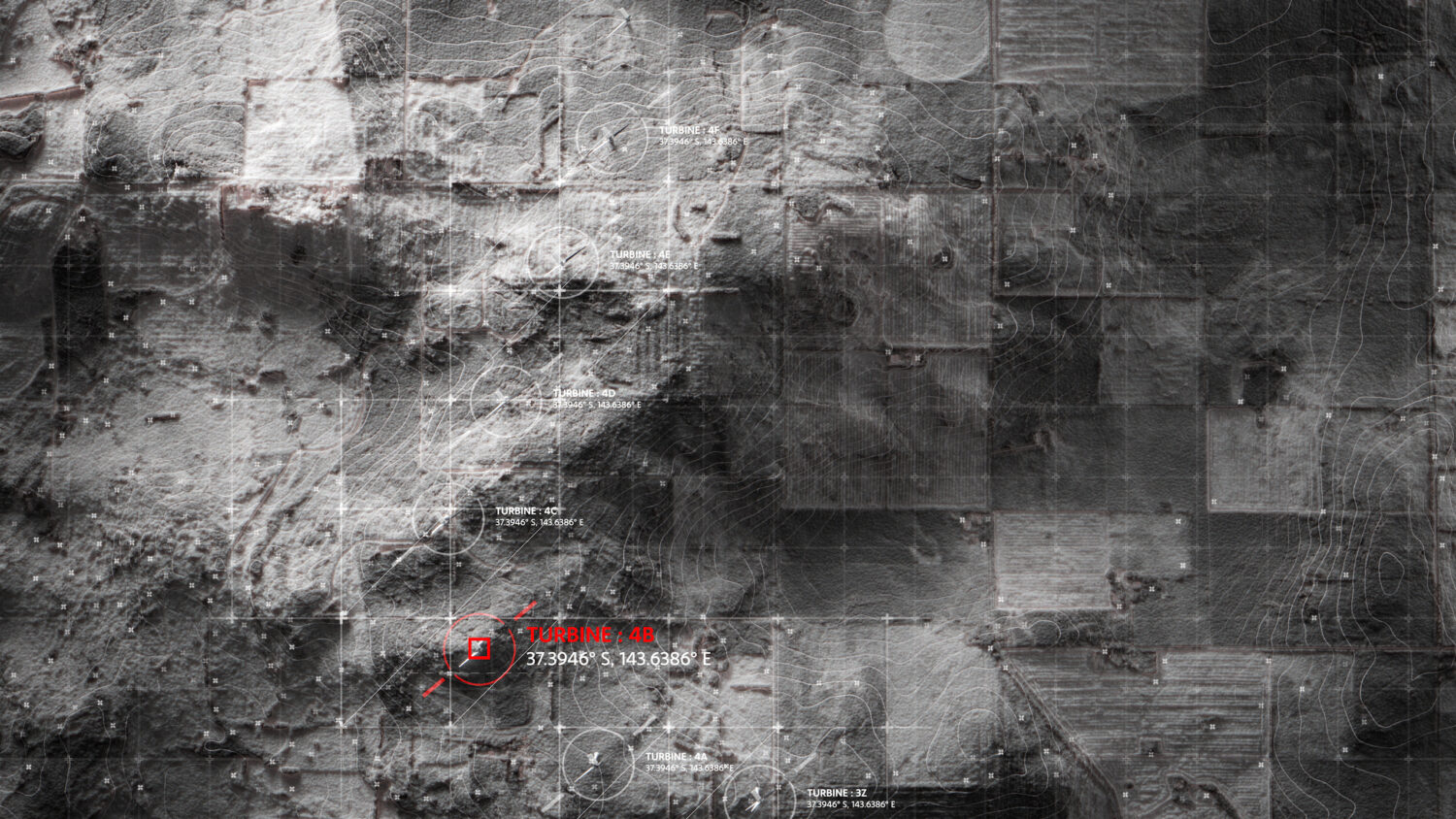

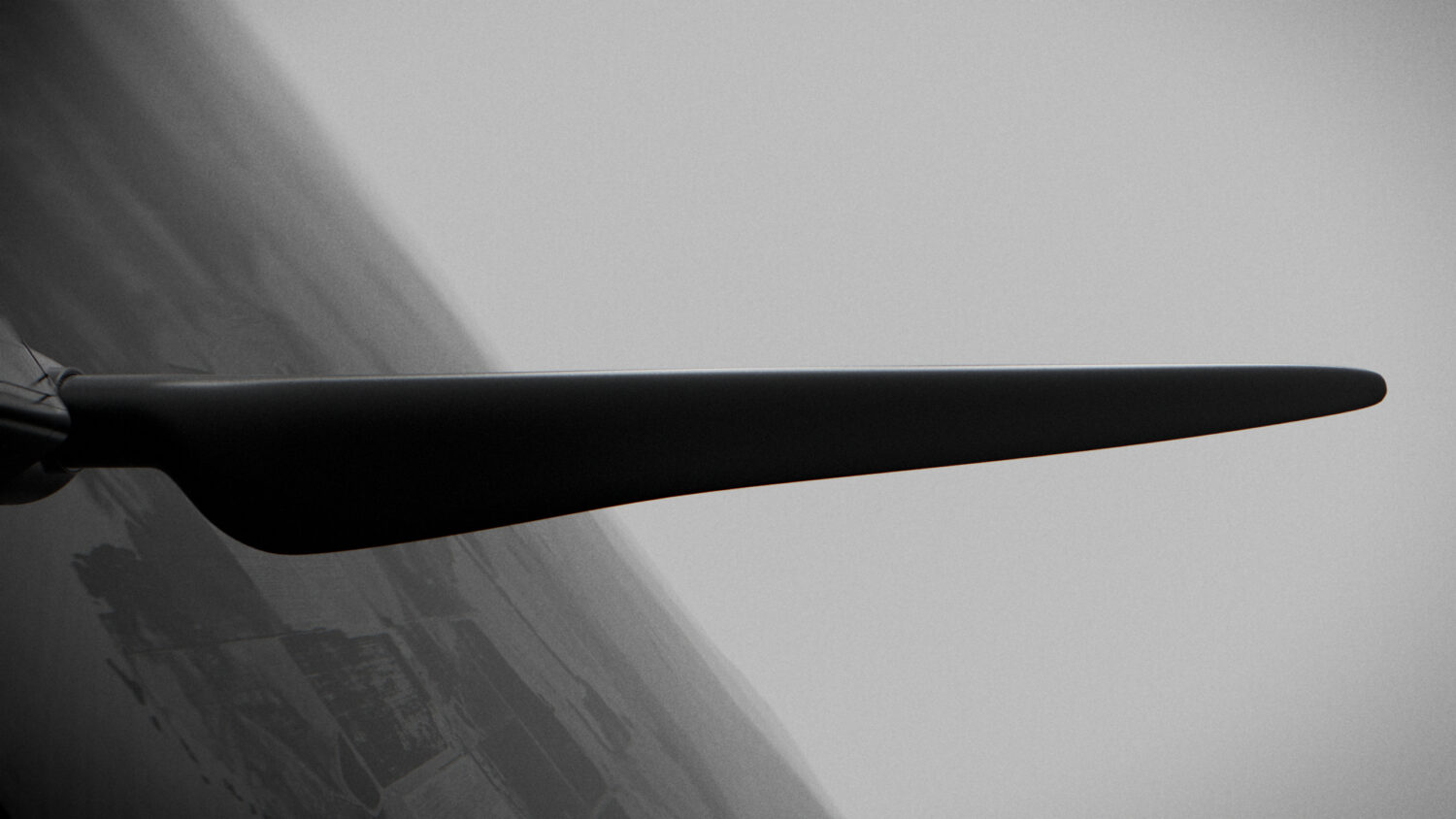

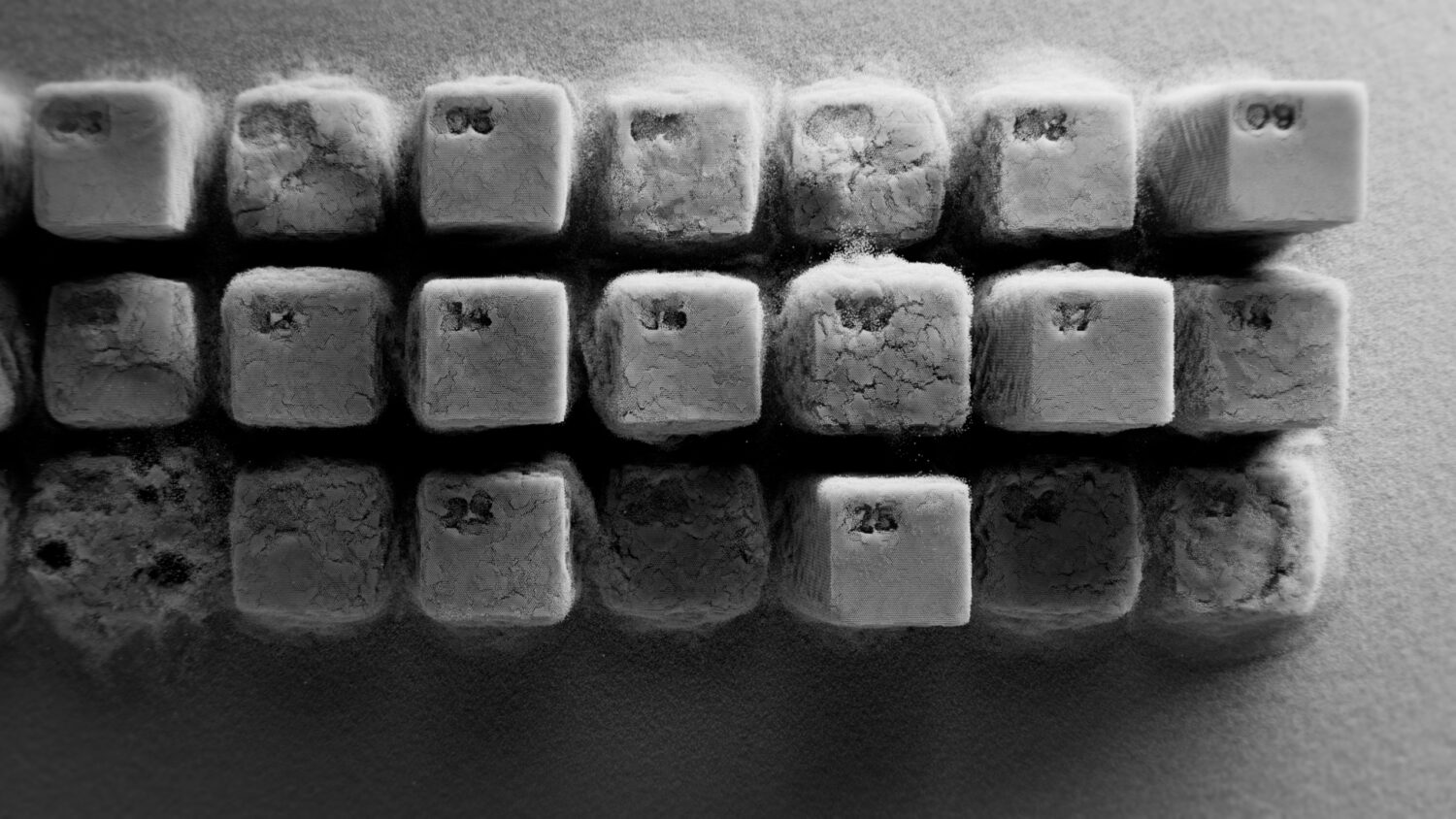

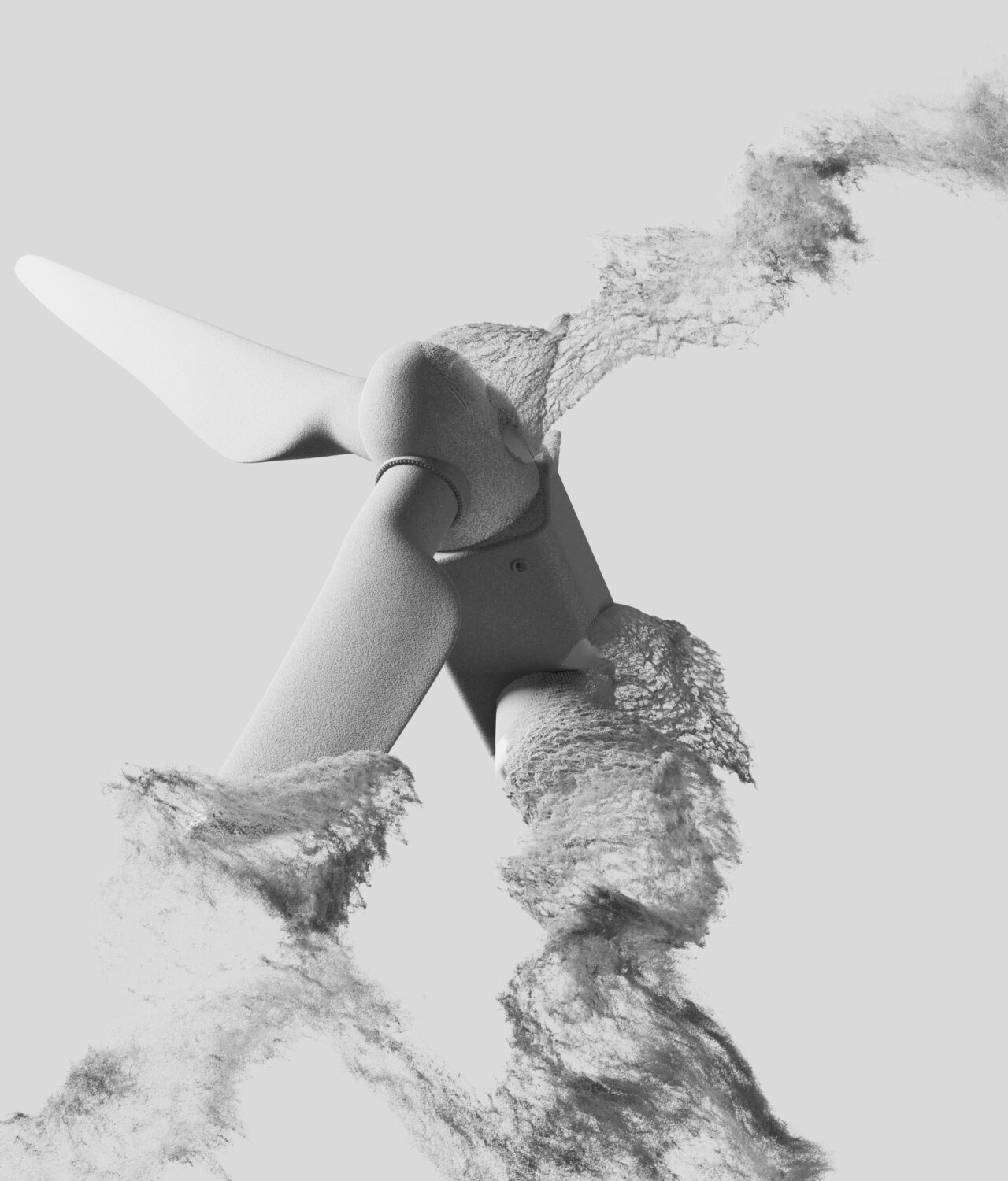

For the launch of the initiative, ACCIONA broke down a decommissioned blade from its Waubra Wind Farm in Victoria into a versatile particulate that could serve as a raw material for sustainable product manufacturing. Like the turbines themselves, the products will help power a more sustainable Australia and could include applications such as protective gear for firefighters, highway crossings for endangered koalas, concrete for sustainable buildings and equipment for playgrounds.

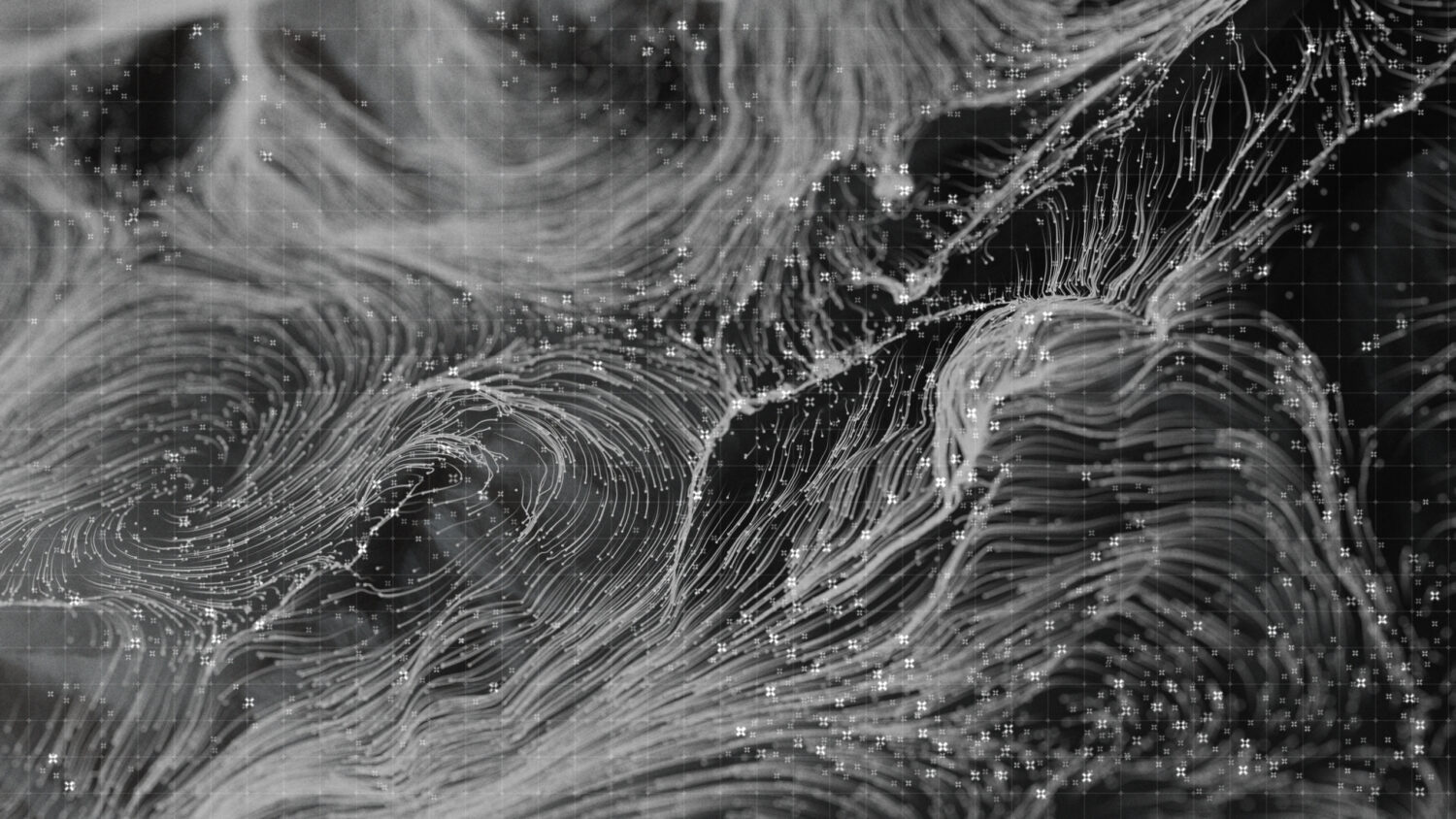

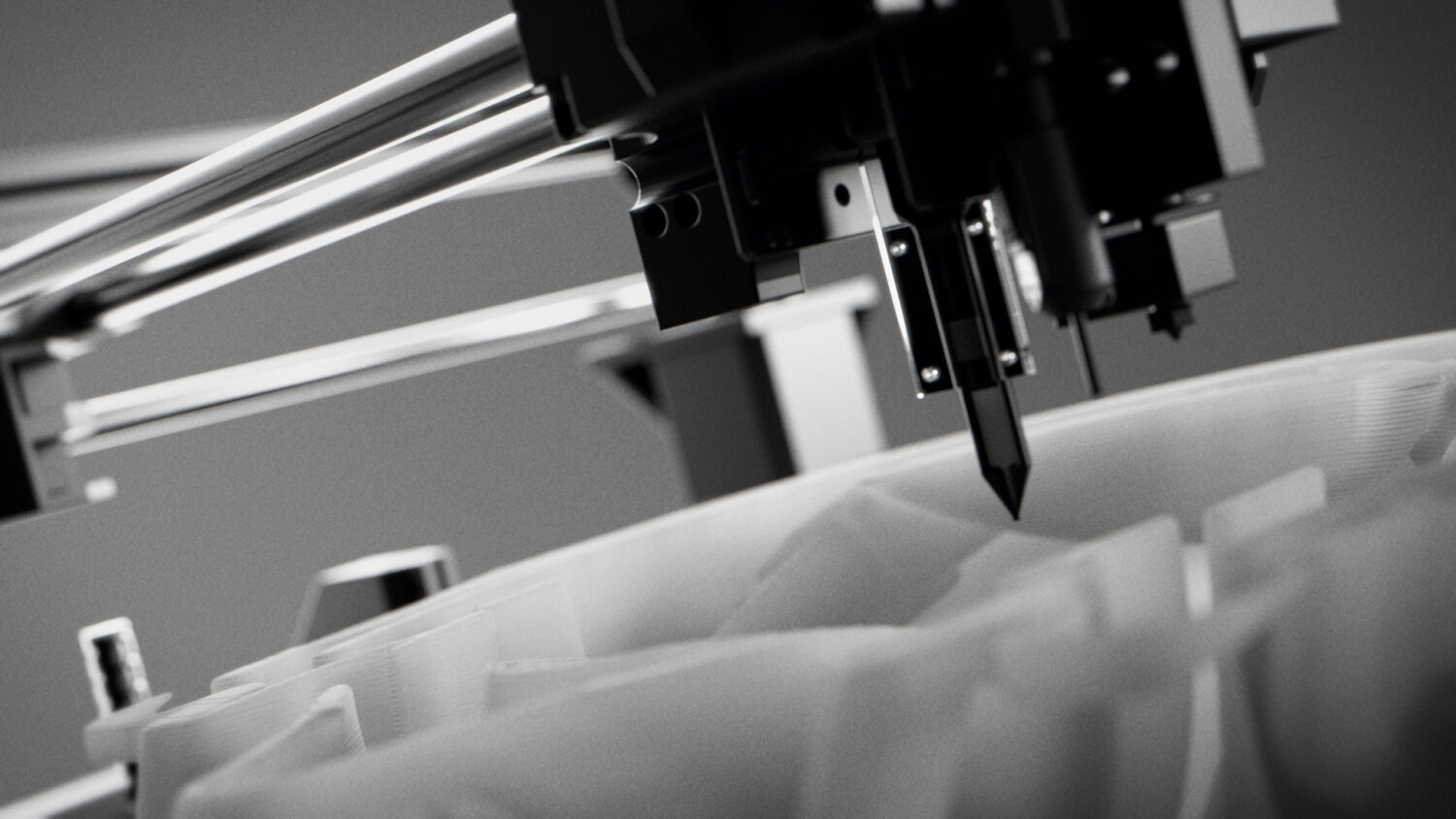

Collider worked with DDB to conceive the story and visual ideas to reflect an aspirational vision for the brand. Hypothetical science inspired visualisations of geographic locations, windflow data, power grids and 3d printing systems were brought to life via complex CG.

Particle animation techniques were used to express the disintegration and reformation of the carbon fibre turbine blades into filament powder.

We also needed to visualise a complete product package and went through a number of design iterations to resolve the final form.